Heating Technology

- Gas Furnaces

Duct furnaces are designed for use in ducted applications with a separate air handling device such as a horizontal blower assembly. By utilizing a separate air source, greater application flexibility in airflow delivery can be obtained. Multiple duct furnaces can be used with an air handling unit to provide zone heating.

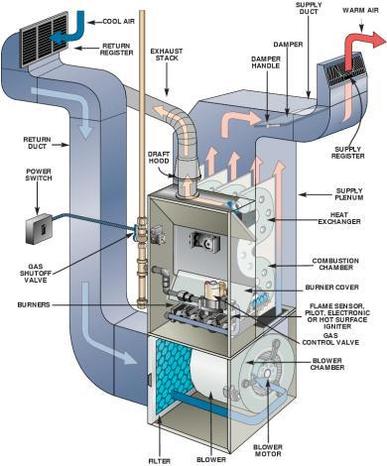

The furnace’s pilot light or electronic ignition lights the burner inside the combustion chamber. This creates heat in the furnace’s heat exchanger, a metal chamber around which the moving air flows.

Once warmed, the air is pushed into the hot-air plenum and then out to the rooms through duct work. The combustion gases created by burning fuel are vented through a flue in the roof or, with high-efficiency furnaces, through a wall.

One of the benefits of a forced-air system is that it can receive a whole-house air-conditioning unit, a humidifier, and an electronic air filter—all of which can take advantage of the furnace’s air handler and ducts for delivery of conditioned air to rooms. Duct work is generally metal wrapped with insulation or a flexible plastic-wrapped insulated material that helps retain heat.

- Hybrid Heat

A Hybrid heat system reacts to changing temperatures and automatically adjusts to the most efficient energy saving method available to heat or cool a home. It can be a fuel-saving alternative to traditional heating and cooling systems in that it combines a furnace with a heat pump, rather than an air conditioner.

A heat pump works as an air conditioner in hot weather, but can also reverse the process and heat the home when cold weather arrives. Rather than burning fuel to generate heat, the heat pump moves heat via the transmission of R-410A refrigerant without burning a flame, using a small amount of energy to move heat from one location to another.

Hybrid Heat can work with both gas and electric systems. By using a variable speed fan, hot or cool air gets distributed consistently and evenly throughout a space. Variable speed fans use Direct Current style motor technology, or ECM Motor.

While local energy costs vary, a heat pump can reduce electricity use by up to 40 percent. A local utility provider or a reputable heating & cooling contractor can provide energy savings analysis via a home energy audit.

- Gas Unit Heater

Propeller fan unit heaters and centrifugal fan gas unit heaters are designed for use in space heating applications. The gas unit heates are typically used in areas with high ceilings, and are exposed in the space to be heated. Gas unit heaters offer low installed cost, and are able to heat large volume areas without requiring extensive duct systems.

Product Features Include:

- Low First Cost

- Easy to Install & Maintain

- Excellent Redundancy

- Geothermal

No matter what climate you live in, the temperature throughout the year varies. For some climates that means blazing summers that cool to frigid winters. What many people don’t realize is that the temperature below ground (regardless of climate or season) stays fairly consistent all year.

The ground is able to maintain a higher rate of temperature consistency because it absorbs 47% of the suns energy (heat) as it hits the Earth’s surface. Water-furnace geothermal systems are able to tap into this free energy with an earth loop. This technology is then used to provide your home or office with central heating and cooling.

Geothermal Heating

During the heating cycle, a geothermal heat pump uses the earth loop to extract heat from the ground. As the system pulls heat from the loop it distributes it through a conventional duct system as warm air. The same heat energy can also be used for a radiant floor system or domestic hot water heating.

Geothermal Cooling

In the cooling mode, the heating process is reversed – creating cool, conditioned air throughout the home. Instead of extracting heat from the ground, heat is extracted from the air in your home and either moved back into the earth loop, or used to preheat the water in your hot water tank.

- Split System Heat Pump

Technically, a heat pump is a mechanical-compression cycle refrigeration system that can be reversed to either heat or cool a controlled space. Installation for this type of system typically consists of two parts: an indoor unit called an air handler and an outdoor unit similar to a central air conditioner, but referred to as a heat pump. A compressor circulates refrigerant that absorbs and releases heat as it travels between the indoor and outdoor units.

Think of a heat pump as a heat transporter constantly moving warm air from one place to another, to where its needed or not needed, depending on the season. Even in air that’s seems too cold, heat energy is present. When it’s cold outside a heat pump extracts this outside heat and transfers it inside. When it’s warm outside, it reverses directions and acts like an air conditioner, removing heat from your home.

One advantage of a heat pump is that it moves heat instead of generating heat, giving you more energy efficiency. Also, it is powered by electricity, so you can save substantially on fuel consumption.

Note: Heat pumps are best for moderate climates, and a supplemental heating source may be needed for lower temperatures. As a year-round solution for home comfort, heat pumps can become a key part of your matched system.

- Ductless Split System

Ductless, mini-split-system heat pumps (mini splits) make good retrofit add-ons to houses with “non-ducted” heating systems, such as hydronic (hot water heat), radiant panels, and space heaters (wood, kerosene, propane). They can also be a good choice for room additions where extending or installing distribution duct-work is not feasible, and very efficient new homes that require only a small space conditioning system.

Like standard air-source heat pumps, mini splits have two main components — an outdoor compressor/condenser and an indoor air-handling unit. A conduit, which houses the power cable, refrigerant tubing, suction tubing, and a condensate drain, links the outdoor and indoor units.

ADVANTAGES

The main advantages of mini splits are their small size and flexibility for zoning or heating and cooling individual rooms. Many models can have as many as four indoor air-handling units (for four zones or rooms) connected to one outdoor unit. The number depends on how much heating or cooling is required for the building or each zone (which in turn is affected by how well the building is insulated and air sealed. Each of the zones has its own thermostat, so you only need to condition occupied spaces. This will save energy and money.

Ductless mini-split systems are easier to install than some other types of space conditioning systems. For example, the hook-up between the outdoor and indoor units generally requires only a three-inch hole through a wall for the conduit. Most manufacturers of this type of system can provide a variety of lengths of connecting conduits, and, if necessary, you can locate the outdoor unit as far away as 50 feet from the indoor evaporator. This makes it possible to cool rooms on the front side of a house, but locate the compressor in a more advantageous or inconspicuous place on the outside of the building.

Mini splits have no ducts, so they avoid the energy losses associated with the ductwork of central forced air systems. Duct losses can account for more than 30% of energy consumption for space conditioning, especially if the ducts are in an unconditioned space such as an attic.

In comparison to other add-on systems, mini splits offer more interior design flexibility. The indoor air handlers can be suspended from a ceiling, mounted flush into a drop ceiling, or hung on a wall. Floor-standing models are also available. Most indoor units are about seven inches deep and have sleek, high tech-looking jackets. Many also offer a remote control to make it easier to turn the system on and off when it’s positioned high on a wall or suspended from a ceiling.

Split systems can help keep your home safer, because there is only a small hole in the wall. Through-the-wall and window-mounted room air conditioners can provide easy access for intruders.

- Boilers

A boiler is a closed vessel in which water or other fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking and sanitation.

The source of heat for a boiler is combustion of any of several fuels, such as wood, coal, oil or natural gas. Electric steam boilers use resistance- or immersion-type heating elements. Nuclear fission is also used as a heat source for generating steam, either directly (BWR) or, in most cases, in heat exchangers called “steam generators” (PWR). Heat recovery steam generators use the heat rejected from other processes such as gas turbine.

Boiler efficiency

there are two methods to measure the boiler efficiency 1) direct method 2) indirect method

Direct method -direct method of boiler efficiency test is more usable or more common

indirect method -to measure the boiler efficiency in indirect method, we need a following parameter like

- Ultimate analysis of fuel (H2,S2,S,C moisture constraint, ash constraint)

- percentage of O2 or CO2 at flue gas

- flue gas temperature at outlet

- ambient temperature in deg c and humidity of air in kg/kg

- GCV of fuel in kcal/kg

- ash percentage in combustible fuel

- GCV of ash in kcal/kg

- Radiant Floor Heat

Radiant heating systems supply heat directly to the floor or to panels in the wall or ceiling of a house. The systems depend largely on radiant heat transfer — the delivery of heat directly from the hot surface to the people and objects in the room via infrared radiation. Radiant heating is the effect you feel when you can feel the warmth of a hot stove-top element from across the room. When radiant heating is located in the floor, it is often called radiant floor heating or simply floor heating.

Radiant heating has a number of advantages. It is more efficient than baseboard heating and usually more efficient than forced-air heating because it eliminates duct losses. People with allergies often prefer radiant heat because it doesn’t distribute allergens like forced air systems can. Hydronic (liquid-based) systems use little electricity, a benefit for homes off the power grid or in areas with high electricity prices. Hydronic systems can use a wide variety of energy sources to heat the liquid, including standard gas- or oil-fired boilers, wood-fired boilers, solar water heaters, or a combination of these sources.

Despite its name, radiant floor heating depends heavily on convection, the natural circulation of heat within a room as air warmed by the floor rises. Radiant floor heating systems are significantly different from the radiant panels used in walls and ceilings. For this reason, the following sections discuss radiant floor heat and radiant panels separately.